I. Customer Background

A large fine chemical enterprise required pressure monitoring for sealed tanks containing hydrofluoric acid (HF) during raw material transfer. Traditional pressure transmitters suffered from short lifespans and low accuracy in highly corrosive environments, leading to frequent replacements, production downtime, and high maintenance costs.

II. Customer Pain Points

- Highly Corrosive Media: Hydrofluoric acid aggressively corrodes metal materials. Conventional 316L stainless steel diaphragms lasted only 1 day.

- Harsh Measurement Environment: Large pressure fluctuations (including negative pressure) in pipelines, with media temperatures consistently between 80°C and 100°C.

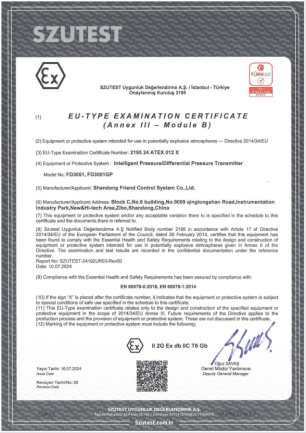

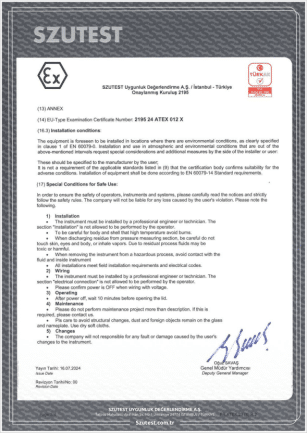

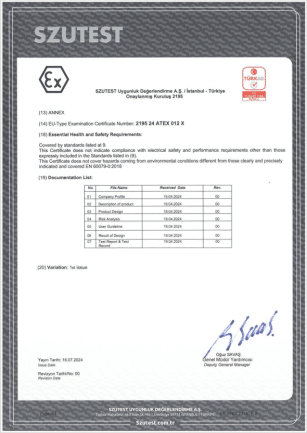

- Safety Requirements: Production area classified as an explosive hazard zone, requiring ATEX explosion-proof certification.

- Data Management Needs: 4-20mA output with HART communication protocol compatibility.

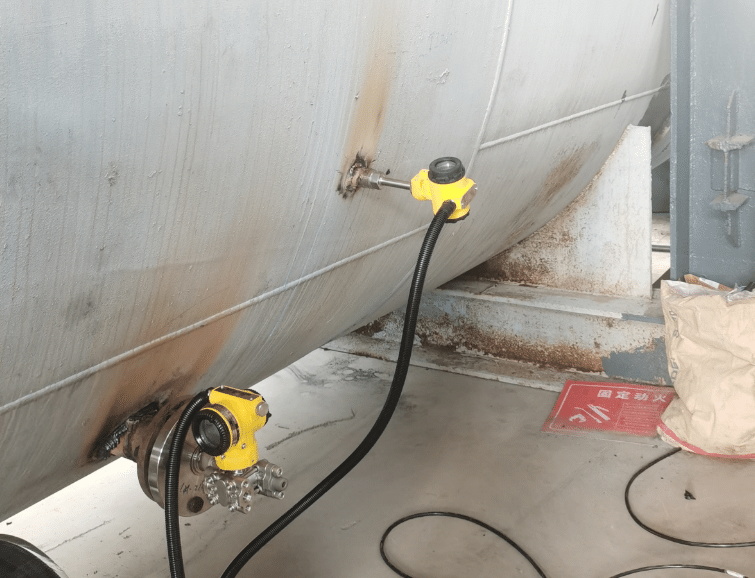

III. FRD Solution

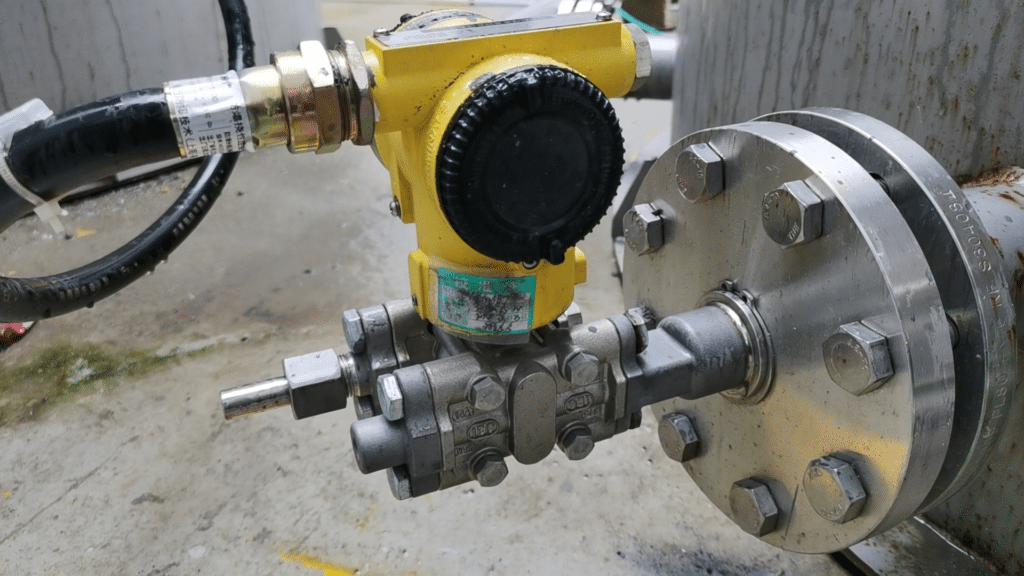

Customized the FD3051SLT Single Flange Pressure Transmitter based on operational demands

Core Material Upgrades:

- Monel 400 Alloy Diaphragm: Nickel-copper alloy offers exceptional corrosion resistance to hydrofluoric acid, significantly extending lifespan.

- Full Monel Cladding on Flange: Combined with stainless steel isolation for complete protection.

Precision Parameter Configuration:

- Range: 0–1MPa (covers full scale from negative to high pressure).

- Accuracy: 0.2% FS (meets ±2kPa error tolerance for process control).

- Temperature Compensation: -30°C to 70°C wide-range design, suitable for nearly all environments except extreme cold.

- Silicone Oil Fill: Withstands -40°C to 200°C, ensuring stability at 120°C media temperatures.

Safety Enhancements:

- ATEX explosion-proof certification.

- Suitable for Zone 0, 1, and 2 hazardous areas.

Smart Communication:

- Standard 4-20mA + HART protocol, supports on-site configuration via handheld terminals.

- Optional RS485 interface for MODBUS RTU communication.

IV. Implementation Results

Enhanced Reliability:

- Monel diaphragm extended transmitter lifespan, reducing annual maintenance costs by over 70%.

- 0.2% FS / 3-years long-term stability ensures consistent operational data.

Optimized Measurement Performance:

- 0.2% accuracy meets ±2kPa process requirements, cutting measurement error by 50% compared to previous devices.

- Monocrystalline silicon sensor achieves 0.2s response time, effectively capturing transient pressure changes.

Safety & Compliance:

- Explosion-proof certification guarantees safe operation in hazardous environments.

- IP66 rating and dust-proof design adapt to harsh chemical plant conditions.

V. Customer Feedback

“The FRD single flange pressure transmitter exceeded expectations in hydrofluoric acid applications. The Monel diaphragm resolved corrosion issues, while the 0.2% accuracy and wide range provided stable data despite severe pipeline pressure fluctuations. The explosion-proof certification also ensured compliance with safety regulations.”

— Equipment Manager, Client Enterprise

VI. Application Insights

For pressure measurement in highly corrosive, wide-range, and explosive environments, the FRD – FD3051SLT series offers a comprehensive solution through material innovation, smart communication, and safety enhancements. Its modular design allows flexible adaptation to diverse operational needs, making it ideal for critical measurement points in high-risk industries such as fine chemicals and petroleum refining.